Instead flywheel energy storage system becomes potential alternative form of energy storage. The flywheel of the machine has a mean diameter of 75 cm and weighs 155 kgcm3.

Flywheel Parts Types Functions Applications Pdf

Ch 9 Problem 39 The flywheel of a gasoline engine is required to give up 500 J of kinetic energy while its angular velocity decreases from 650 revmin to 520 revmin.

. R Mean radius of flywheel ρ Density of flywheel material ω Angular speed of flywheel v Linear velocity of flywheel and. It feels like a stutter or vibration when released. Cast steel 7800 kgm 3.

This paper considers the problem of a mechanical system design with a variable moment of inertia. 43 Analysis of design-C. Now J f and m f are 113962 kgm 2 and 135130 kg respectively.

The Density of the materials d is as follows. The flywheel design problem is then formulated as a numerical optimization problem with the coefficients of the thickness function as its design variables and the minimum and maximum thicknesses of the flywheel as its constraints. σt Tensile or hoop stress.

Procedure Selection of the engine Calculation of torque due to inertia forces The total Inertia force Q M x Data. Numerical Problems on Flywheel Design Turning Moment Diagrams Maximum Fluctuation of Energy Dimensions of a Flywheel Rim Dynamics of Mach. Tentatively four sectional blocks are cut from the flywheel and the design-C is made as in Fig.

PATEL INSTITUTE OF TECHNOLOGY DESIGN OF FLYWHEEL Prepared by- Dhiren P. Design of Flywheel and Simple Solved Problems on Flywheels. Stress distribution and KE of Geometry 1 with Cast Iron.

Consider a small element of the rim as shown shaded in Fig. 2142006 ACRME2092006 2142006 ACRME2092006 Design of a Flywheel. Choose a suitable value for coefficient of fluctuation of speed and calculate mass moment of inertia I of the flywheel.

In the design calculation of a solid disk flywheel various parameters are used as inputs. The material of flywheel on most applications will be either cast iron or cast steel. Given the state of development of flywheel batteries it is expected that costs for flywheel can be lowered with further technical development.

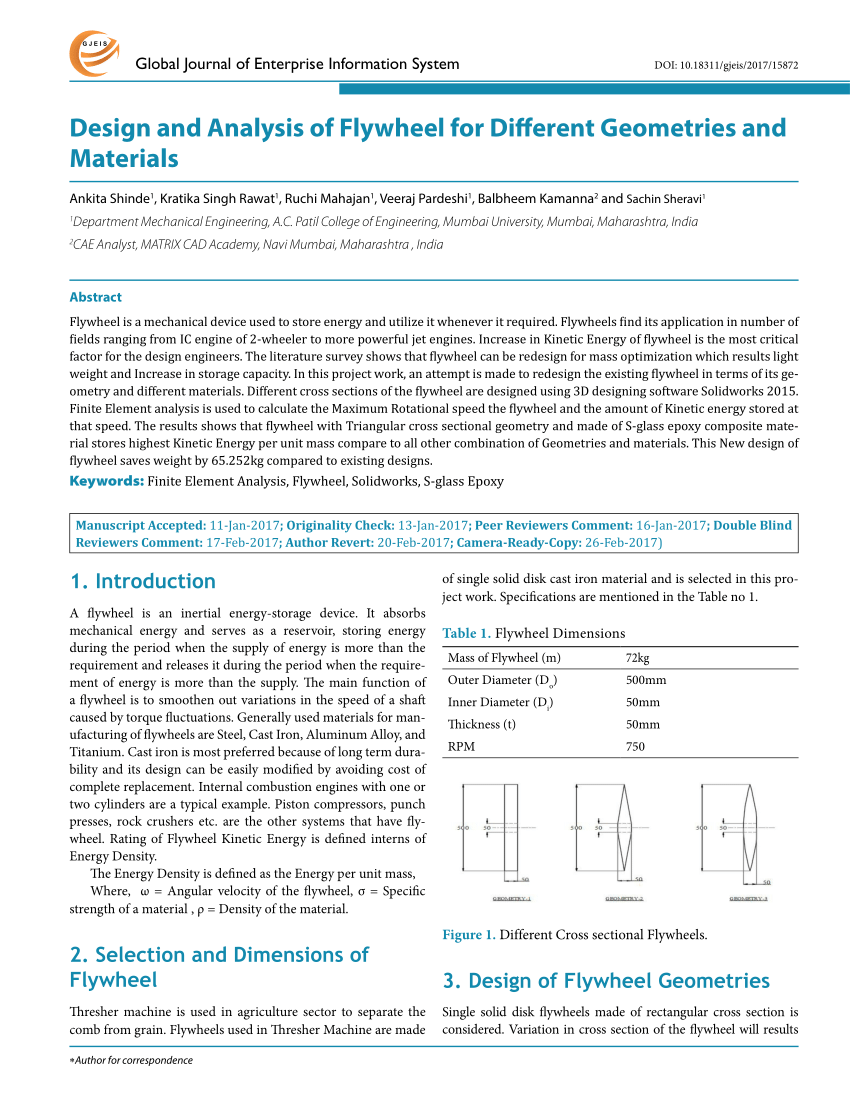

Different Cross sectional Flywheel Models. The automobile will not start and once all other mechanical problems are determined to be in good condition the operator needs to have the flywheel inspected to determine whether it is loose or missing gear teeth which causes this starting problem. Design of flywheel 1.

This problem occurs when finding it difficult engaging the clutch. 431 Analysis and Result. Under such a situation and being aimed at a practical mechanism system the project is.

Procedure Design of a Flywheel. 45 Flywheel Design 451 Mass Moment of Inertia of Flywheel for an IC Engine 452 Mass Moment of Inertia of Flywheel for a Punching Press 453 Design of Flywheel 46 Summary 47 Key Words 48 Answers to SAQs 41 INTRODUCTION In practice there are two following types of cases where reciprocating engine mechanism is used. Calculation of the flywheel.

Arial Comic Sans MS Times New Roman Default Design 1_Default Design Microsoft Equation 30 Slide 1 Slide 2 Slide 3 Slide 4 Rotation about a Moving Axis Total Kinetic Energy. A flywheel is usually coupled to the crank shaft to limit the fluctuation of turning moment and hence the fluctuation of speed. Flywheel energy storage systems are in use globally in increasing numbers.

This includes the dimensions of the solid disk flywheel. A flywheel energy storage system or flywheel battery is a mechanical battery that stores energy kinetically in the form of a rotating mass and uses the inertia of the spinning mass to store or generate power. A large flywheel is needed to smooth the output from a single cylinder engine as excessive vibration can cause.

431 Analysis and Result. R1 Flywheel inner radius. The solid disc flywheel is equipped with a flywheel hub and disc.

Cast iron 7250 kgm 3. INTRODUCTION FLYWHEEL- A flywheel is an inertial energy-storage device. It absorbs mechanical energy and serves as a reservoir storing energy during the period when the supply of energy is more than the.

Decide the type of flywheel to be used the material of the flywheel and the allowable. A number of industrial incidents have occurred. The suggested system consists of a rotating disc with the ability to change the angle of inclination by means of a rod and a slider mounted on the rotation axis.

Design of Flywheel and Simple Solved Problems on Flywheels. Up to 5 cash back Chapter Objectives. Determine the maximum fluctuation of energy from torque versus angular displacement diagram for a given problem.

No codes pertaining specifically to flywheel energy storage exist. This New design of flywheel saves weight by 65252kg compared to existing designs. Design equations and techniques are described making possible the dynamic.

There are two stages to the design of a flywheel. Figure 1 - Flywheel Design. The design-C is analyzed at its four typical working stages respectively.

This protocol recommends a technical basis for safe flywheel design and operation for consideration by flywheel developers users of. This problem is not only made in the flywheel but in the flywheel or crankshaft assembly bearing or bushing. Table1 shows the comparison among chemical battery and flywheel energy storage system.

Clutch chatter often happens in any gear popularly when starting from a complete stop. 1First the amount of energy required for the desired degree of smoothening must be found and the mass moment of inertia needed to absorb that energy determined. Figure 4-6 Design-C.

Let it subtends an angle δθ at the centre of the flywheel. 2 Cross-section of a flywheel rim. Choose a suitable value for coefficient of fluctuation of.

It skips along with the flywheel as the clutch grabs and releases the flywheel repeatedly. 43 Analysis of design-C. 2Then flywheel geometry must be defined that caters the required moment of inertia in a reasonably sized.

R2 Flywheel outer radius. Kinetic energy is the energy of motion as quantified by the amount of work an object can do as a result of its motion expressed. Flywheel Design Critical Dimensions.

For The Following Problems It May Save Some Hunting Chegg Com

Pdf Design And Analysis Of Flywheel For Different Geometries And Materials

How Do Flywheels Store Energy Explain That Stuff

Flywheel Design And Sizing Calculation Example

Modeling Optimization And Detailed Design Of A Hydraulic Flywheel Accumulator Hydraulic Accumulator Optimization Hydraulic Energy Storage

0 comments

Post a Comment